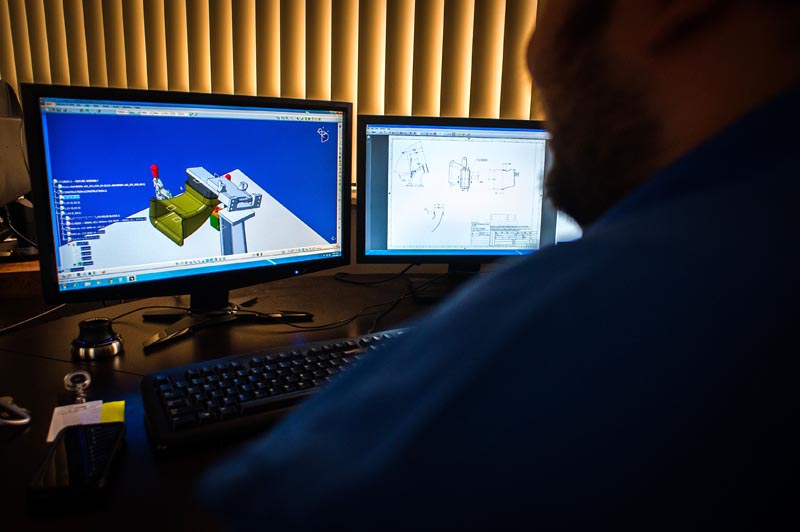

Design & Engineering

We provide complete design and build techniques for production and prototype tooling. From the initial design, to the final product, we’re fully equipped to handle every aspect of your prototyping needs. Our automated software and technology-driven capabilities are state-of-the-art. We work with our clients every step of the way to ensure we’re meeting their standards and expectations.

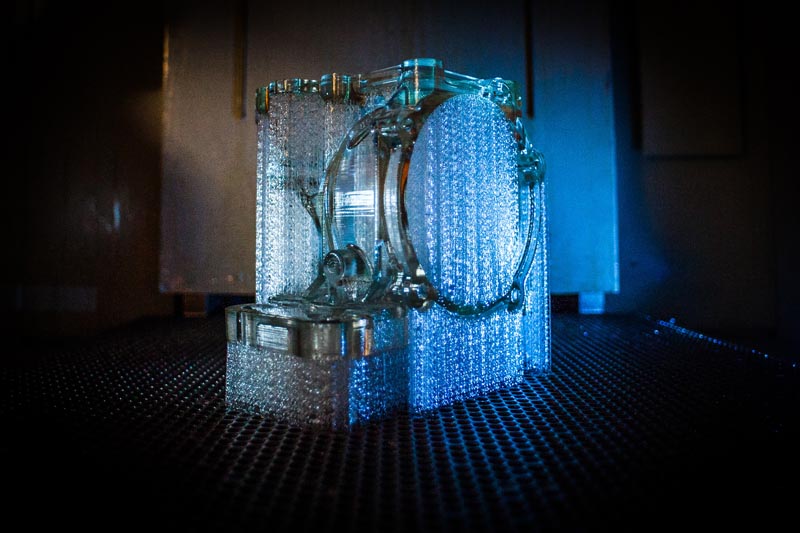

Rapid Prototype

Working with us means you will have physical prototypes back within days. Whether you need SLA, SLS, FDM or Urethanes, we’re proud of our ability to have detailed quotes back to our clients within days. Let’s get your next project started!

Tool Building

Quality prototype and limited production tooling to meet any requirements, that’s our promise. We are able to accommodate any and all design request that are sent our way, and have a variety of build options to choose from. CPS offers tooling in silicone & epoxy, aluminum, kirksite and steel. Work with our experienced team to decide which process is best for your budget.

Tool Tryouts & Molding

Our facilities host a number of molding services, all industry leading and fully functional. Whether you are looking for injection molding, blow molding or reaction injection (RIM) molding – CPS is your answer. Our facilities have the ability to run 24/7 to meet your critical program needs.

Assembly, Painting & Welding

Our assembly and welding departments cover a wide range of functions. Some of our in-house offerings include Robotic Welding in our metals group, to Vibration welding for plastics. Whether you need metal stamping assemblies or molded plastic assemblies and components – we’ve got you covered.

Fabrication

High-quality and complete fabrication services are hard to come by. That’s why we’re so proud of our in-house services. We offer constant engineering support and design assistance with all of our orders. We love a good challenge! If you have a new design concept we want to help you bring it to life. We specialize at precision fabrication with a number of different materials. Our assembly processes are accurate and efficient.

Laser Cutting

CPS has the capacity you need to cover all your Laser Cutting needs. Between our 3 axis flat and 5 axis laser cutters we have the ability to cut up to 13 mm, covering a wide array of materials including metals, plastic & composite.

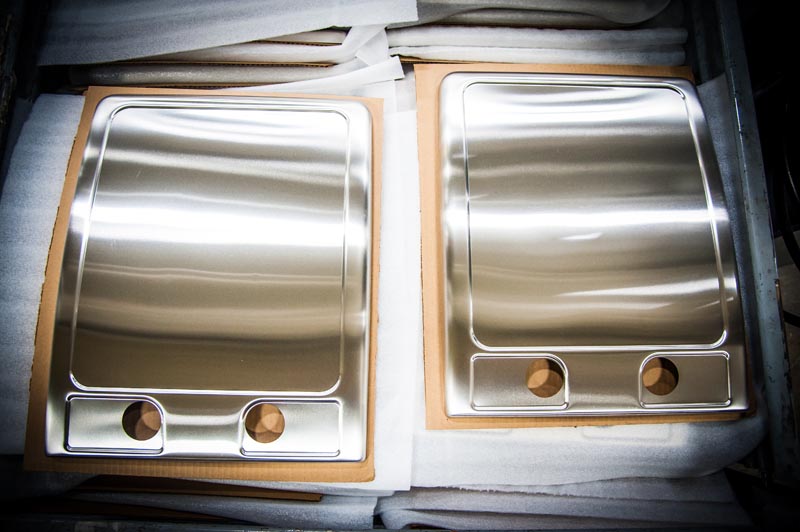

Stamping

We work with a number of design requirements, which we can deliver at a cost effective price. We produce all of our stampings at our in-house stamping facility in Fraser, MI. Our varied press sizes can handle a heavy workload, meaning we work on even the biggest of jobs.

Quality & Inspection

At CPS, we hold quality to the utmost value. It’s one of the main pillars of our company. We’re constantly assessing your project from start to finish to ensure that all quality control regulations are met. Our team is trained to inspect your tools and prototypes after every step of the way, so you can rest assured knowing that when your project is done, it’s done right the first time.